In the fall of 2017, Lillia was awarded a grant of $1,500 to research and complete a collection focused on the new age of fashion technology, 3D Printing for Mass production. This grant is designed by Texas Woman's University to generate experiential learning that focuses on enhancement of student learning through a process where students develop knowledge, skills, and values from direct experiences outside a traditional academic setting.

With this grant and a passion to understand the growing technological curve in the industry, Lillia set out to design a collection that could be mass produced and 3D printed for the apparel market. The project grew into more as Lillia spiked interest in NCUR 2018, National Conference for Undergraduate Research, and was approved to give an oral presentation at the conference for April 2018 on her findings from research. Below you will find a selection of her findings and digital illustrations of the collection.

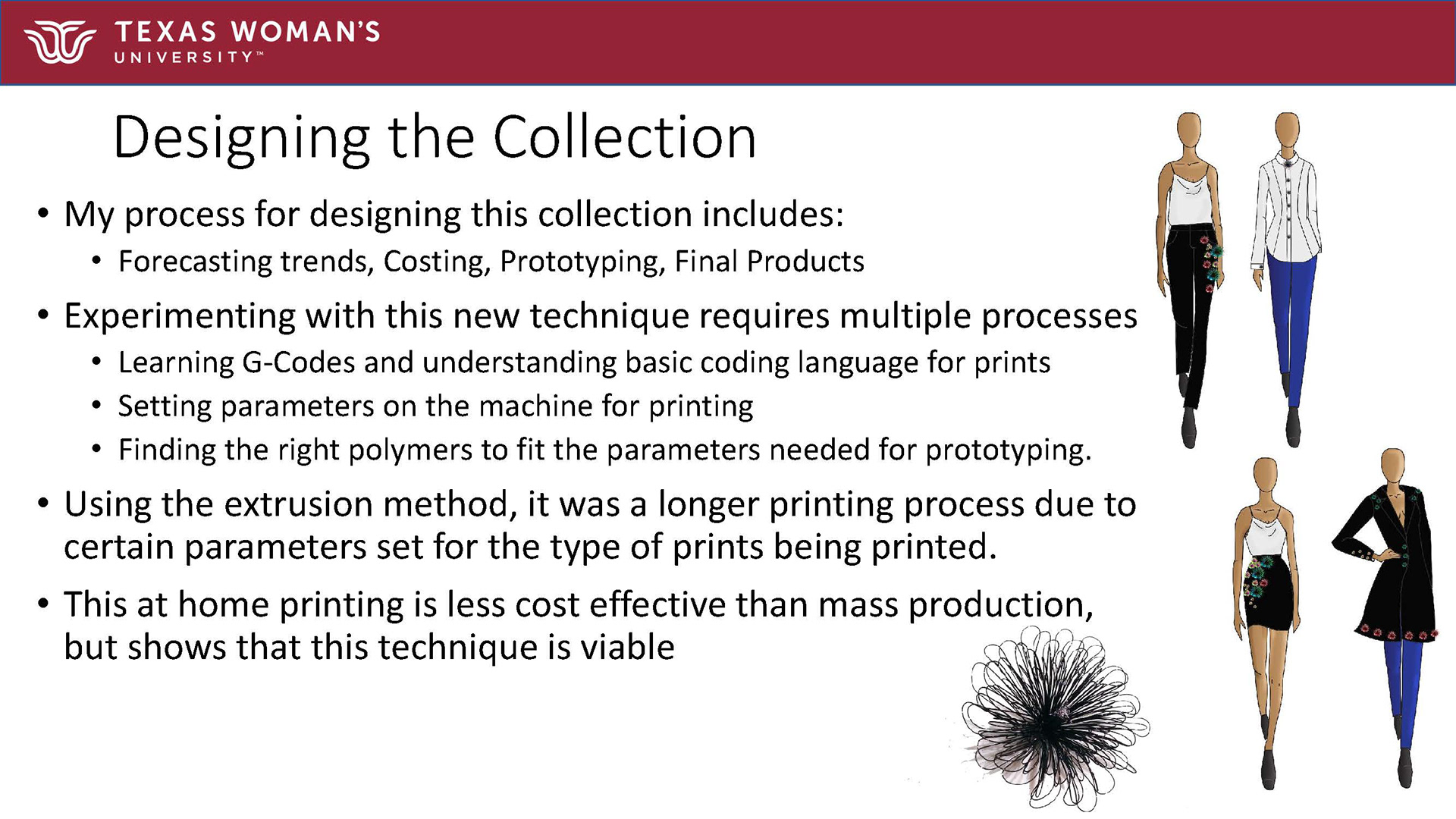

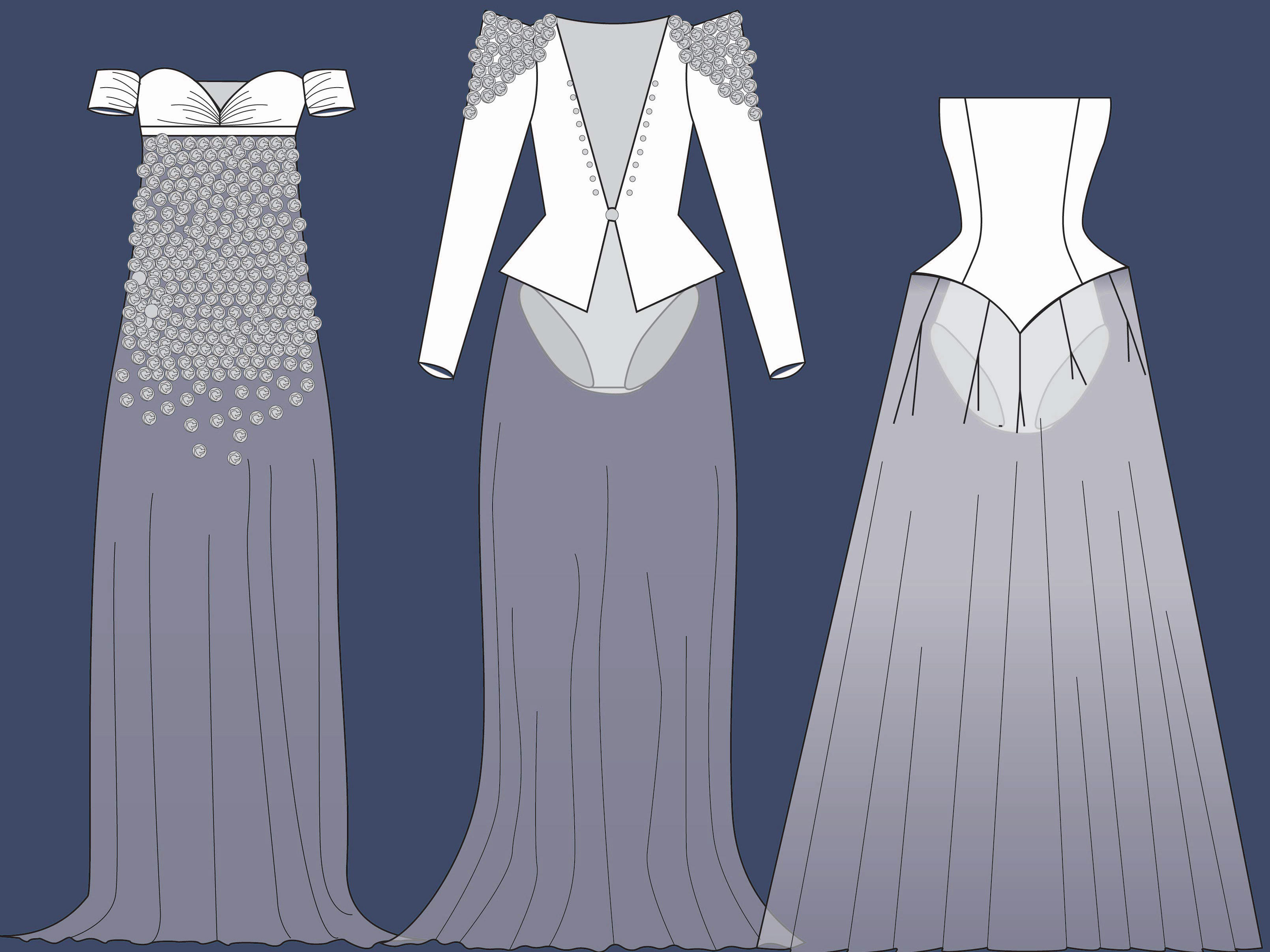

To incorporate 3D printing into the collection, the 3D applique will have a fully functional purpose. The 3D printing will be created separate from the garment and sold separately from the garment so that way the customer can completely customize the garment for their own tastes or occasion. Having the pieces be detachable also allows the original garments to be machine washable, a must in the retailed fashion world. Following the millennial trends as well, enamel pins are popular in fast fashion, as well as higher end stores, such as Forever21, Anthropology, Zara, and even Neiman Marcus. With the 3D printed component of the garments resembling pins, it is relatable to the young customer.

The 3D printed flowers are called drooloop flowers and are a popular way to print flowers in the 3D industry. By researching current trends for applique and topical embelishments,this method of 3D printing seems viable to the target customer, young women who are entering the job field who aspire to have a sustainable and fashionable wardrobe.

At the National Conference on Undergraduate Research in April 2018, the research was adjusted to focus on the sustainability effortsin the industry by using 3D printing as a mass production technique. The fashion industry as a whole produced 15.1 million tons of textile waste in 2013, and that’s just the US. That is not including fashion hubs of UK, France, Asian countries, or more. With the demand for fast fashion growing, and a growing awareness of environmental needs, companies are turning to 3D printing as a possible alternative for durable and a longer clothing life. One of the unfortunate downfalls as of now is technology for 3D printing is still expensive, and on occasions, hard to acquire.But some companies have found startups to partner with as US manufacturing facilities for 3D printing for mass production.